drill press brinell hardness tester|brinell hardness tester instructions : manufacturing Brinell Hardness Tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for ensuring product quality, reliability, and performance. This test reveals vital information . 16 de out. de 2023 · Conclusão: Como ganhar 300 reais em 1 dia. Neste artigo, exploramos diversas maneiras de ganhar 300 reais em apenas um dia. Discutimos ideias e sugestões para alcançar esse objetivo, como ganhar dinheiro online com tarefas simples, investir em ações e fundos imobiliários de alto rendimento, tornar-se um motorista de .

{plog:ftitle_list}

29 de dez. de 2023 · 1 view 1 minute ago. Nesse dia em que nosso Bispo diocesano Dom Beto Breis parte para o estado de Alagoas, onde assumirá no próximo dia 06 de janeiro .

Details. The Lead Hardness Tester Standard Model is one of the easiest to use lead testers on the market. Use for testing cast bullets and ingots. Features a large and easy to read dial . The Wilson BH3000 Brinell Hardness Tester stands as a robust Brinell hardness tester, boasting a wide range from 62.5 kgf to 3000 kgf. .For testing large flats it enables test heads to be used under large drill presses, boring mills, arbor presses and beams that are capable of withstanding 3000 kg load. Calibrated accurate .

Brinell Hardness Tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for ensuring product quality, reliability, and performance. This test reveals vital information .

DEFINITION OF THE BRINELL HARDNESS TEST The Brinell hardness test was originally developed in the late 1800s by the Swedish engineer of the same name. He wanted to find a method to control the quality/hardness of steel. His .The B.O.S.S. from Newage is a Brinell optical scanning system that includes a high resolution video scanning head and imaging software that ensures a fast, accurate, and consistent reading of all Brinell impressions.

Hardness tests can be defined as forcing an hardness testing indenter of a specified size, shape, and material into the surface of a test piece to obtain a hardness value. Skip to content +1 847-295-6500

The HRB scale typically is used for soft materials such as aluminum and brass alloys. It uses a 1/16-in. ball indenter with a 100-KG test force. Brinell Testing. Brinell testing normally is used for larger, heavy-walled pipe. Because the Brinell test is not a depth-measuring technique, it is more forgiving.The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide).The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is .

Our webshop offers online sales of accessories such as hardness test blocks, anvils, and indenters for Rockwell, Brinell, Vickers, Knoop hardness testing at an affordable price. Visit the webshop here. RECENT NEWS. Acquire the most accurate and easy way to .King Portable Brinell Hardness Testers are the most reliable, easy to use and affordable portable Brinell testers that are certified and calibrated per ASTM E-10 standards and the ONLY portable Brinell testers on the market that are accurate to within 1% with traceability to NIST.Discover precision and reliability with Multitek Technologies' Brinell Hardness Tester. Explore our cutting-edge equipment for accurate material hardness testing, ensuring quality and efficiency in your industrial applications. 1038521826884939 top of page. HOME. ABOUT US. PRODUCTS. SERVICES. CALIBRATION. CERTIFICATIONS. CONTACT US.

The Brinell hardness testing method is used in various cases where large or rough surfaces, coarse-grained materials, or high loads are involved. It is particularly well-suited for testing the hardness of materials with relatively low hardness ranges, such as non-ferrous metals, castings, and softer steels.BRINELL HARDNESS TESTER MODEL NB-3010 Including Appendix for Retrofit of HB3000 to NB3010 OPERATING INSTRUCTIONS V 1.0 Issue 06/2016. Contents 1. APPLICATION INFORMATION 1 . idle, the spring presses the main shaft in the conical hole and cause the rod to remain close to the middle knife support of small lever (29) so as to keep the rod in the .The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters.

The Newage KB Series is a popular, manually-controlled Brinell hardness tester that meets ASTM E-110. This lightweight, portable tester is ideal for virtually any size or shape of metal specimen. The Newage KB Series is a popular, manually-controlled Brinell hardness tester that meets ASTM E-110.The operator inserts an impact pin (G) into the impact head (E) and presses the indenter against the pin, puts the impact head into the impact sleeve and puts it into the holder. . PINS-250 Ernst - Package of 250 Calibrated Pins Class G .

As an easy-to-operate and high-precision hardness tester, a hydraulic standard type that has been widely used for 60 years. The load is loaded by a manual hydraulic pump. This machine is usually mainly used for testing materials such as rails, springs, castings, forgings and structural parts, especially for castings with coarse metal grains.Non-standard methods in Brinell HBT in a load range of 294-1,839 N (30-187.5 kg) Versions: . Portable hardness tester for measurements in drill holes; Drill hole diameter from 36-110 mm; Test process: The testing instrument is . The Brinell hardness test uses a spherical indenter which is pressed, by a precisely controlled force – most commonly 3,000 kgf – into the material being measured. The force builds between two and eight seconds then is sustained for several more to ensure that the indentation is a plastic deformation (see footnote). The diameter of the .Universal hardness testers are designed for hardness testing according to Brinell, Vickers, Rockwell and Knoop, as well as plastics testing and carbon testing.To cover all of these test methods, the universal hardness testing machine supports a wide load range. ZwickRoell universal hardness testers therefore provide a flexible solution with a load range from 0.3 to .

Brinell [HB] is one of the most common units used for listing the hardness of steel materials. the test is done with a 10 mm steel ball pressed with 3000 Kgf (6,614 Lbf). Common values for machined materials range from 100 HB for very soft materials up to 650 HB for heat-treated steels.. The advantage of Brinell [HB] over Rockwell [HRC /HRB], is that the whole range is .And this hardness tester can act as both a bench type or portable hardness tester for use in the field. The PHT-5050 portable Brinell hardness tester meets all Brinell standards, including ASTM E-110, and relevant Brinell hardness tester standards from ISO, JIS and GB. Lifetime technical support is included on all Phase II Hardness Testers.Brinell Hardness Tester is a rapid and accurate method to determine hardness value with ASTM E-10 compliance. Applying loads of up to 3.000 kgf, the Brinell test is ideal for castings and forgings. Skip to main content [email protected] 1-877-884-8378 .

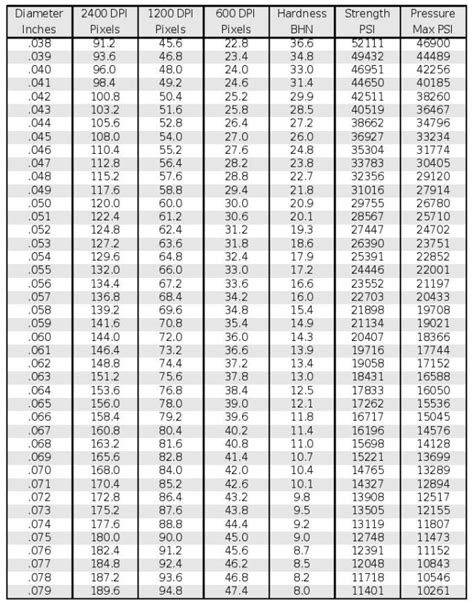

This accessory gives the operator of the King Portable Brinell Hardness Tester the functionality and freedom of testing a part with the ability to view the gauge from either the front side or the back side of the part. . This adapter holds the test head upright and is ideal for drill presses, boring mills and beams. The Brinell hardness test measures material hardness by determining the diameter of an indentation made by a hardened steel or carbide ball under a specific load. A load, typically ranging from 500 to 3,000 kgf, is applied to the material’s surface for 10-15 seconds, allowing the ball to penetrate and create an indentation. . Drill Press Lead BHN Hardness Tester. Posted By North Carolina Prepper on June 27, 2016 . Just using my Harbor Freight Drill Press and a 10 dollar bathroom scale. If you don’t have a drill press you could use a big “C” clamp as well. To get the Brinell Hardness Number of a lead ingot. Full disclosure : You should really use a ball at the .

And this hardness tester can act as both a bench type or portable hardness tester for use in the field. The PHT-5050 portable Brinell hardness tester meets all Brinell standards, including ASTM E-110, and relevant Brinell hardness tester standards from ISO, JIS and GB. Lifetime technical support is included on all Phase II Hardness Testers.The Brinell hardness test method often presents some challenges for users. Poor operating conditions, inexperienced users, tedious high-volume testing and demanding applications contribute to reduce accuracy and repeatability. Newage Brinell testers can meet these challenges and help ensure accurate, consistent results.

lee brinell hardness tester chart

brinell hardness testing machine diagram

brinell hardness testing charts

Ultimate X Poker Online. Video poker is one of those games t.

drill press brinell hardness tester|brinell hardness tester instructions